Everything You Need to Know About CNC Machining for Aerospace

There’s a lot of buzz around the topic of CNC machining for aerospace. But what is it? And what does it mean for the industry? This blog post will break down everything you need to know about CNC machining for aerospace, including what it is, how it works, and why it matters.

What is Computer Numerical Control (CNC)?

CNC machining is what you might call a “mighty giant” within the precision machine tools industry. It’s an additive manufacturing process that can work with various metals, from aluminum to titanium. The precision machining process uses computer software and precision tools to transform raw metal blocks into finished parts.

Applications of CNC Machining in the Aerospace Sector

The precision CNC machining process is vital for the aerospace industry because it’s used to create some of the most precision parts on earth, whether precision aircraft parts or precision aerospace components. Some of its applications include:

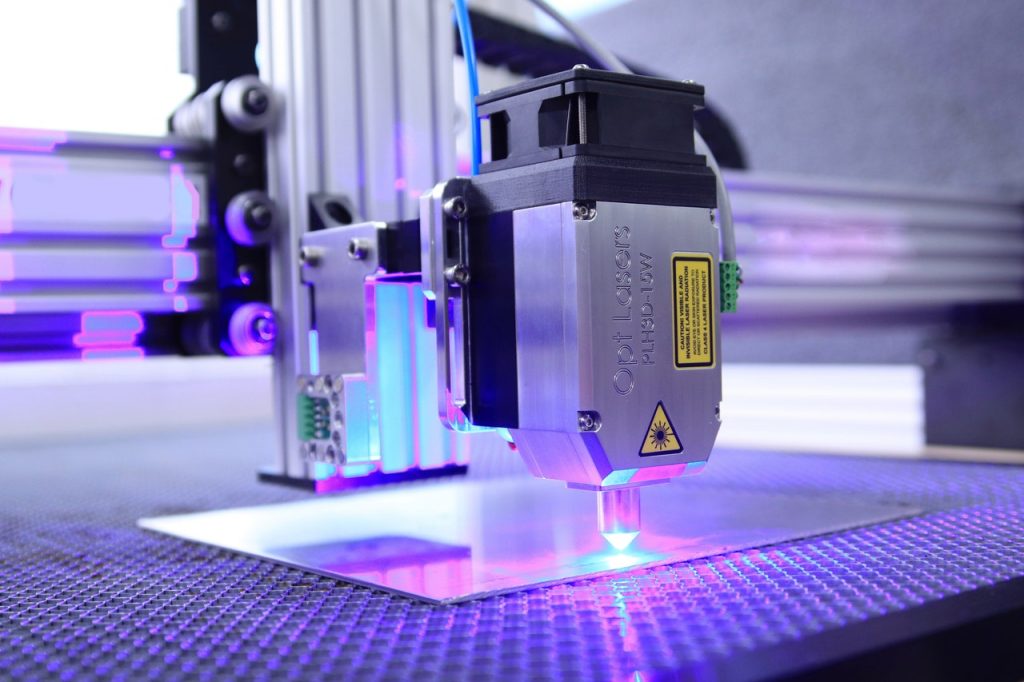

1. 3D Printing and Production

CNC machining for aerospace plays a vital role in revolutionizing the 3D printing and production industry. The precision CNC machining process can print some of the most precise components on earth. In fact, Boeing uses the precision CNC machining process to build more than half of its aircraft parts.

2. Designing Specifications for Components

Before precision CNC machining in the aerospace industry, the only way to design a precision metal component was by hand. Engineers first had to build a precision model of the component and then send it to a machinist. The machinist would use tools like a lathe or mill to handcraft the precision metal piece.

The precision CNC machining process for aerospace changed all that by laying the foundation for computer-aided design (CAD). This precision machining technology allows engineers and designers to create CAD models of precision parts using 3D modeling software. They can then use precision CNC machining to manufacture the precision parts in record time.

3. Welding for Structural Components

Welding is one of the most popular precision CNC machining processes for aerospace component manufacturing. Why? Because it’s one of the most cost-effective precision machining processes available. The precision CNC machining process combines welding equipment and tools to create precision structural components.

Benefits of CNC Precision Machining in The Aerospace Industry

The aerospace industry faces many challenges, from the rising cost of skilled labor to issues with supply chain management. CNC precision machining is an excellent solution for any company, big or small, that’s looking to cut these costs. Its benefits include:

- It is faster than other precision machining techniques like Electrical Discharge Machining (EDM), saving companies time and money.

- Precision CNC machining for aerospace is versatile. It can produce precision parts in less time than other precision machining techniques.

- It is computerized. This machining process can produce consistent parts without extensive knowledge of CNC technology.

- It is scalable. It can create parts of any size, design, or specification.

- CNC precision machining requires less manual labor. It can work unattended for extended periods.

CNC precision machining is a process that’s revolutionizing the aerospace industry. This machining technology has transformed precision metal fabrication. Companies use precision CNC machining to produce precision parts quickly and cost-effectively.