How Aerospace Fasteners Drive Innovation in Modern Aircraft Design

Key Takeaways

- Fasteners are crucial components in ensuring aircraft safety, durability, and performance.

- The aerospace industry continues to innovate in fastener materials and technology to support lighter, more efficient aircraft.

- Adhering to global standards and rigorous testing is vital to meet safety regulations and industry requirements.

- Advances in fastener technology support cutting-edge trends like additive manufacturing and composite materials.

- Future developments in aerospace fasteners will likely center around sustainability, intelligent monitoring, and further weight reduction.

Table of Contents

- The Role of Fasteners in Aircraft Safety

- Material Selection: Lightweight Yet Strong

- Precision Manufacturing and Quality Assurance

- Global Standards and Regulatory Compliance

- Technological Advances in Fastener Design

- Integration with New Aircraft Materials

- Current Challenges and Future Trends

- Conclusion: Fasteners for the Next Generation of Aircraft

The Role of Fasteners in Aircraft Safety

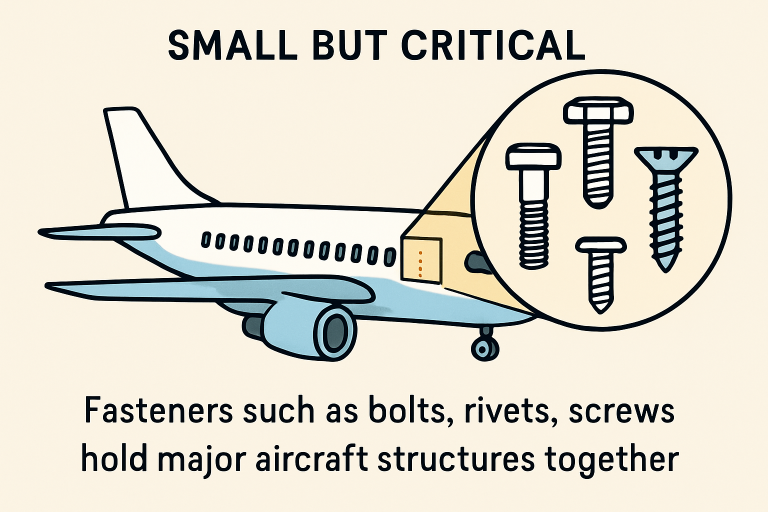

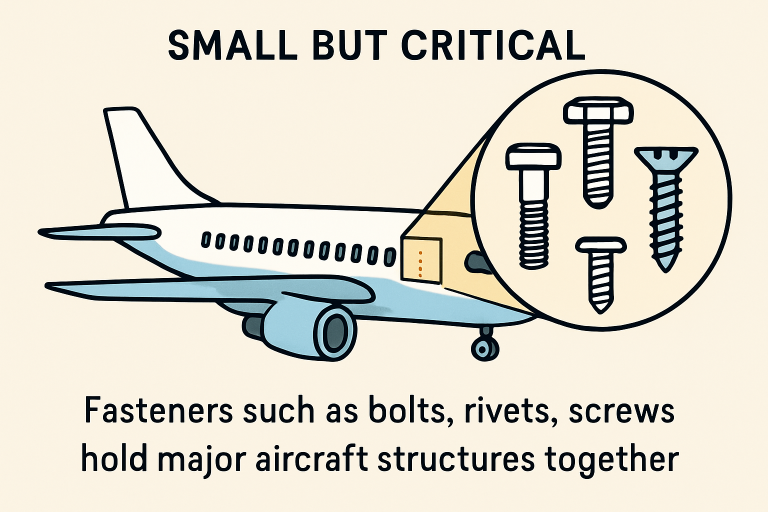

The integrity of every aircraft in operation hinges on a complex network of components, but none are more discrete yet critical than fasteners. These small, engineered parts form the backbone of aircraft assembly, ensuring that structural loads are evenly distributed and essential systems remain securely fastened under extreme operational conditions. The dependency on reliable fasteners has never been more pronounced as passenger safety and regulatory compliance become ever more stringent within the aviation sector.

Sourcing high-quality parts is paramount for all aerospace stakeholders. Trusted hardware distributors help manufacturers access certified, state-of-the-art fasteners designed for the unique demands of flight. This careful procurement process, backed by technical expertise, ensures that each rivet, screw, or bolt upholds stringent industry standards, minimizing the risk of failure and maximizing operational reliability.

A single failed fastener can compromise the safety of an entire flight, as seen in past incidents analyzed by the Federal Aviation Administration. This makes frequent inspection and maintenance a non-negotiable aspect of aircraft operations. Maintenance engineers rely heavily on documentation, traceability, and certified fastener sources to keep fleets airworthy and compliant.

In modern aircraft, fasteners have evolved to do more than hold structures together—they also support modular designs that allow for quicker part replacement and streamlined maintenance. This advancement is integral as airlines seek to reduce aircraft downtime and improve service intervals, highlighting fastener technology’s silent but indispensable role.

Material Selection: Lightweight Yet Strong

The aerospace sector continually pushes the limits for weight reduction while maximizing structural performance. The materials chosen for fasteners help realize these goals. Titanium offers a remarkable combination of lightness and strength, significantly reducing aircraft weight without compromising safety. High-strength steel and aluminum alloys are other workhorse materials, prized for their resistance to corrosion and ability to withstand repetitive loading cycles—an ever-present challenge in aviation.

Aerospace engineers are now experimenting with advanced materials like carbon fiber composites and hybrid alloys. These innovations will lead to even lighter and more efficient aircraft, simultaneously reducing fuel consumption and environmental impact. Material science will further improve fastener performance and reliability as larger aircraft and new airframe concepts emerge.

Precision Manufacturing and Quality Assurance

Rigorous manufacturing protocols govern the journey from raw material to aerospace fastener. Techniques like cold heading, precision heat treatment, and advanced surface finishing are standard in the fastener industry, ensuring each component adheres to microscopic tolerances. Every production lot undergoes multiple layers of inspection—including X-ray analysis and non-destructive testing—to root out flaws before parts ever reach the assembly line.

Ensuring quality goes beyond initial production. Leading aerospace firms work closely with suppliers on continuous improvement initiatives and employ robust traceability systems to track each fastener from manufacturing to installation within the aircraft, as highlighted in this feature by The New York Times. These efforts are reinforced by surprise audits and ongoing qualification processes required by aviation authorities worldwide.

Global Standards and Regulatory Compliance

Aerospace fasteners must consistently perform across extreme conditions and diverse operational requirements. Meeting international standards like AS9100 and ISO is essential for fasteners to be accepted for use in global fleets. Oversight bodies, such as the Society of Automotive Engineers (SAE), issue updated technical specifications that address the latest engineering advances and safety risks.

Regulatory compliance guarantees compatibility across aircraft models and establishes a benchmark for quality and security. Manufacturers and hardware distributors must implement comprehensive documentation, which enables global traceability and supports seamless aircraft certification processes.

Technological Advances in Fastener Design

The digital revolution is shaping fastener development. Engineers now leverage computer-aided engineering (CAE) tools to simulate complex loading scenarios and optimize fastener geometries for weight, stress, and ease of installation. Additionally, the rise of 3D printing allows for rapid prototyping and the exploration of non-traditional fastener shapes, significantly quickening the path from concept to application.

As Forbes highlighted, additive manufacturing is redefining how aerospace companies innovate, bringing custom fastener solutions for unique airframe designs. These design tools and production methods translate into more adaptable and efficient fastening systems, aligning with the evolving demands of next-generation aircraft.

Integration with New Aircraft Materials

Introducing advanced composite and hybrid materials to aircraft structures brings unique fastening challenges. The interface between metals and composites can induce galvanic corrosion, which manufacturers counter with specialized coatings or non-metallic isolators. At the same time, the aerospace sector is moving toward more bonded joints, although mechanical fasteners remain essential at highly loaded or safety-critical locations.

Another priority is reducing the number of fasteners required while maintaining safety and structural integrity. Through thoughtful integration and engineering, aircraft designers limit unnecessary hardware and exploit synergies between fasteners and composite subassemblies. This approach leads to lighter, more durable, and streamlined airframes.

Current Challenges and Future Trends

The fastener industry is at the forefront of sustainability and digital transformation. Manufacturers are developing recyclable fasteners and experimenting with biocompatible coatings to reduce environmental impact. Meanwhile, “smart” fasteners with embedded sensors provide real-time load and stress monitoring, driving predictive maintenance programs that increase efficiency and asset availability.

The emergence of urban air mobility, electric propulsion, and unmanned aerial vehicles (UAVs) presents ongoing technical and regulatory challenges. Fastener solutions must continue to evolve, addressing new thermal environments, vibration profiles, and installation requirements to meet the needs of increasingly complex aerospace systems.

Conclusion: Fasteners for the Next Generation of Aircraft

Aerospace fasteners may seem insignificant compared to the larger innovations in jet engines or avionics, but their role is vital to the evolution of flight. Each new aircraft design leverages improved fastener materials, more intelligent monitoring systems, and advanced manufacturing to ensure safer, more efficient travel. For anyone invested in the future of aviation, understanding the innovation journey behind the smallest components is essential to anticipating what the next generation of aircraft will achieve.