A Definitive Guide to CNC Machining Equipment

CNC machining is a process in which a computer-controlled machine is used to make various products. Unlike manual machining, CNC can handle a variety of materials and reduce a business’s labor costs. CNC technology is widely available and more accessible to use than ever before.

CNC Machining is a Subtractive Process

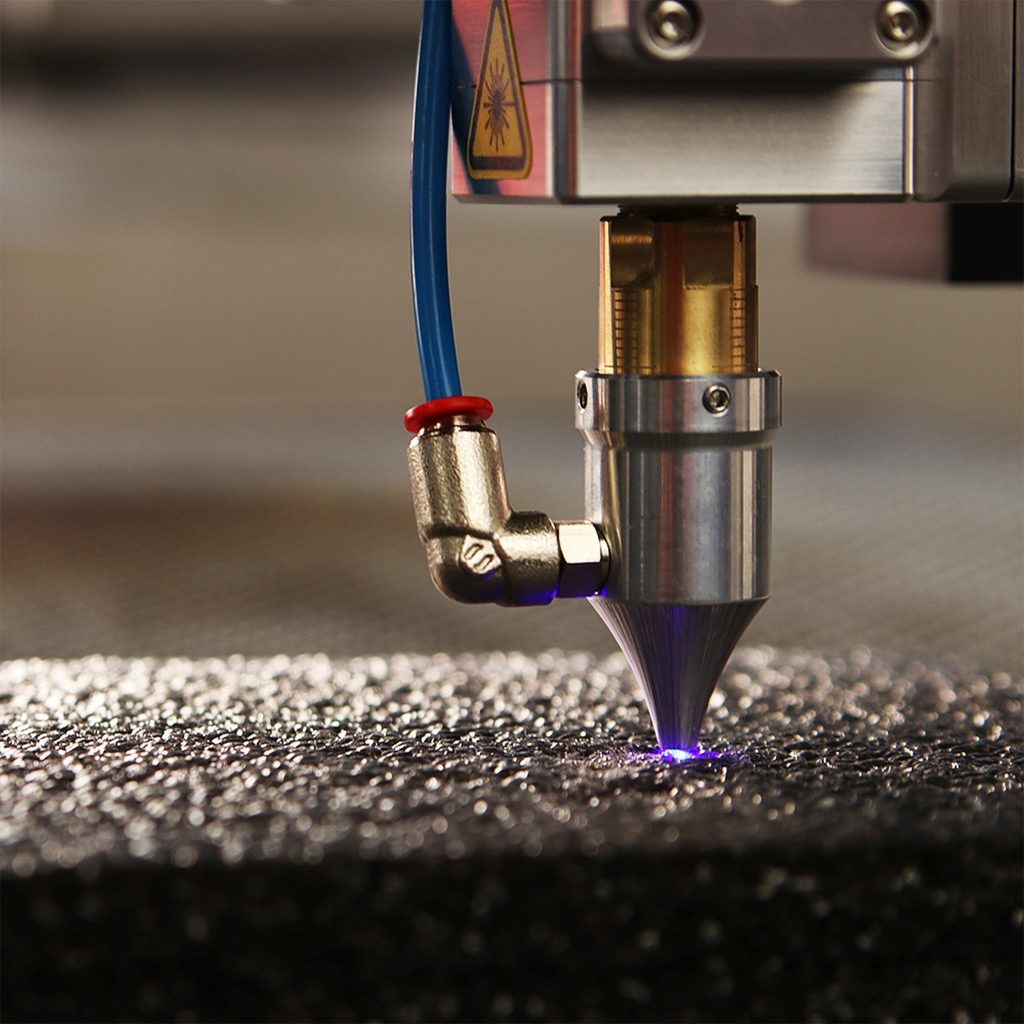

CNC machining is a process that makes products and parts from a solid piece of material. Most certified machine shop Houston, TX, use this process to be highly accurate and can be used on various materials. It is more efficient than the additive process and can produce parts quickly. It also uses a smaller amount of material than the additive process. This method is also fully automated, making it ideal for large-scale production.

CNC machining uses computer numerical control (CNC) technology to direct and coordinate the movement of cutting tools to achieve a specific geometry. This process is used for various materials and is typically more expensive than additives. This type of manufacturing is used to manufacture most metal products.

It Reduces Manual Machining Labor.

CNC machining equipment is a popular option for many industries because it reduces the manual labor needed to produce a part. Its advantages include improved accuracy and repeatability. Additionally, CNC machines can be monitored remotely, which reduces the risk of a breakdown. In addition, CNC machines are more energy efficient and sustainable than manual machining, which can result in significant savings.

Another benefit of CNC machining equipment is the reduced cost of machining parts. Because these parts are produced in large volumes, the cost of making one part will decrease. Additionally, the cost per unit part is minimized because the same machine setup is used to produce many parts of the same design.

It is More Accessible Than Ever Before

CNC machining equipment uses computer-controlled programming (G-code) to create parts. Traditionally, machinists wrote G-code by hand, but newer software helps automate this process by taking a 3D model and creating instructions for the machine to follow. Its automation offers several benefits over manual methods.

CNC machining begins with a CAD design. The CAD design can be a 2D vector or a 3D solid part. If you do not know how to create a CAD design, you can use a CAD/CAM design service company. This software allows designers and manufacturers to create renderings, models, and technical specifications of parts and products.

There are many types of CNC machining equipment. Some are more expensive than others, while others are more affordable. Three-axis machines move in one or two axes, while five-axis machines can move in all three axes. They are an excellent option for small shops and hobbyists. They are affordable, and they are easy to learn and operate.

It is More Efficient.

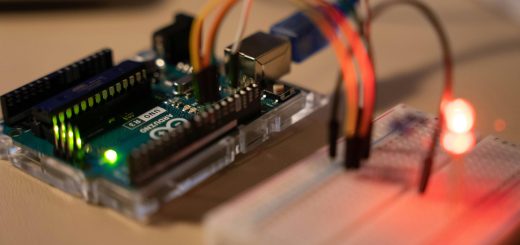

The Internet of Things (IoT) allows machines to communicate, allowing for proactive maintenance and troubleshooting. For example, if a part is overheating or experiencing an increased vibration, an IoT-connected sensor can detect the problem and alert management to fix it. This can help keep production costs down and workplace injuries to a minimum.

Industrial Internet of Things (IIOT) devices can be integrated with CNC machining equipment to increase efficiency. They are connected to ERP software and can be programmed to perform various functions. These systems can also be integrated with machine data to monitor production and help manufacturers plan and schedule work.