Synthetic Diamond, Quality and Characteristics

Synthetic diamond is the one produced in technological processes. That is to say, the hand of man. Facing the natural diamonds that are created by geological processes of nature. In the year 1797, British chemist Smithson Tennant discovers that the diamond is nothing more than a mineral composed of carbon. The possibility of imitating the crystalline form of this chemical element opens the way for the synthesis of the diamond.

Applications

– Machining and cutting tools: Most industrial applications of synthetic diamonds have been associated with their hardness; this property makes this type of diamond the ideal material for machinery and cutting tools. Element Six is a leading supplier of synthetic diamonds for cutting, grinding, drilling, and other tools.

– Thermal conductor: For electronics, the diamond is used as a heat sink for high-power laser diodes, laser arrays, and high-power transistors. Efficient heat dissipation extends the useful life of electronic devices and reduces the high cost of replacing them.

– Optical material: Diamond is hard, chemically inert, and has high thermal conductivity and a low coefficient of thermal expansion. These properties make the diamond superior to any other existing window material that is used for the transmission of infrared radiation and microwaves.

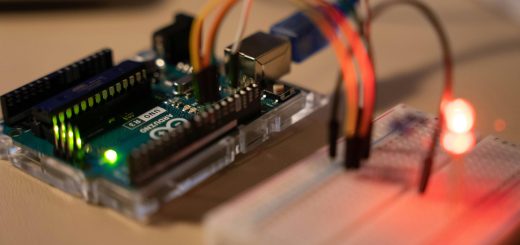

– Electronics: Synthetic diamond has potential uses as a semiconductor.

The arrival of synthetic diamonds to the jewelry industry

In the 90s, synthetic diamond takes its first steps in the jewelry industry. The synthetic diamond sector today is very much fought by the big competitors. We are talking about Gemes is in Florida, Apollo Diamonds in Boston, LifeGem in Chicago, and online casinos us. The estimate of the production of synthetic diamonds in a year is more than 3,000 million carats. That is 600 tons of synthetic diamonds. This product is superior to the 26 tons of natural diamonds that are extracted annually from the mining deposits.

The procedures for making a synthetic diamond

With the HPHT (high-pressure high-temperature) procedure, the process of “high pressure and high temperatures”, the carbon is subjected during a prolonged period to a high temperature (1,400ºC) and a strong pressure (58,000 ATM). This technique is called HPHT.

In addition to the CVD (chemical vapor deposition) procedure, the “Chemical Vapor Deposition” procedure, the synthesis of the diamond is carried out through a chemical deposit in the vapor phase. This is how the artificial layers of the diamond are formed.

According to real money online casinos, these two processes still dominate the production of synthetic diamond, although there are other methods.

Other characteristics of synthetic diamond

Other characteristics are its thermal conductivity and electronic mobility. That’s why synthetic diamonds are used in abrasives. And also as polishing and cutting tools. It is also widely used in corrosive media due to its high resistance to acids. So its use is also frequent in electrochemistry. Moreover, when immersed in pure water, there is no chemical reaction that affects the diamond’s electrodes. So there are many electronic applications that use synthetic diamond due to its thermal properties.